In the world of disinfectants and sterilizers, few compounds can match the versatility and potency of peracetic acid. Particularly at a concentration of 35%, this powerful substance is an essential tool in a multitude of industries. If you haven’t heard much about peracetic acid before, don’t worry. Today, we’ll unpack everything you need to know about this incredible compound and its growing impact across a wide range of fields. Get ready to dive into the science, uses, benefits, and the critical precautions for handling peracetic acid in its concentrated form.

So, What Exactly is Peracetic Acid?

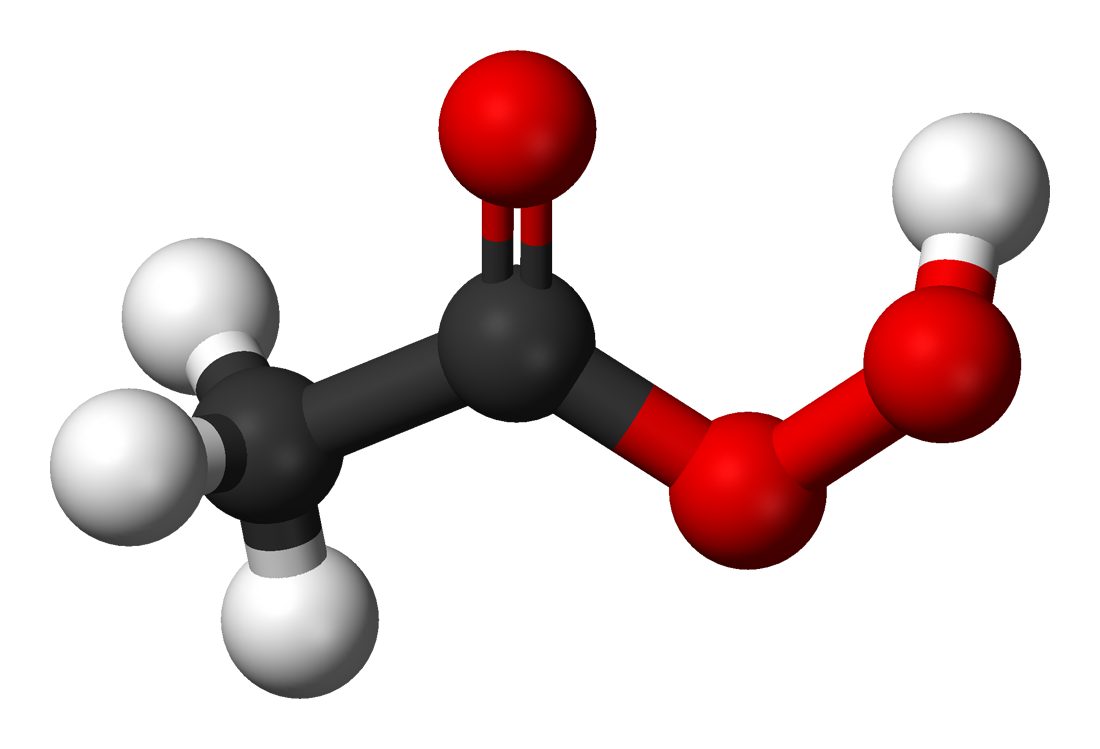

Let’s start with the basics. Peracetic acid is a highly reactive liquid chemical that is made from a mixture of acetic acid (the main component of vinegar) and hydrogen peroxide. At 35%, it’s one of the most potent forms available, meaning its oxidizing capabilities are significantly enhanced.

Peracetic acid shares some similarities with other disinfectants, but its oxidative power sets it apart. When it comes into contact with organic matter, it quickly breaks down, eliminating bacteria, viruses, fungi, and spores in its path. The result is a thorough and efficient disinfection process, perfect for industries where sanitation is a top priority.

Why Choose Peracetic Acid 35%?

1. Broad-Spectrum Effectiveness One of the most appealing aspects of peracetic acid is its ability to combat a wide variety of harmful microorganisms. From bacteria like E. coli and Salmonella to viruses, fungi, and spores, peracetic acid 35% leaves nothing to chance. In fact, it’s so effective that it’s often a go-to solution for everything from food safety to medical sterilization.

2. Eco-Friendly and Residue-Free One of the standout benefits of peracetic acid 35% is that, after it does its job, it breaks down into harmless byproducts: acetic acid (which is essentially vinegar) and oxygen. This means it doesn’t leave behind harmful residues that could pose a risk to people or the environment. Unlike other disinfectants, which can leave toxic traces, peracetic acid’s simplicity in its breakdown makes it one of the more eco-friendly solutions.

3. Works in Cold Temperatures Unlike many disinfectants that lose effectiveness at lower temperatures, peracetic acid 35% stays potent even in cold environments. This is particularly useful for industries that require sanitization in refrigerated or cold storage settings. Whether it’s food products, medical supplies, or water treatment systems, peracetic acid doesn’t require heat to perform its best, which makes it incredibly versatile.

Key Uses of Peracetic Acid 35%

Given its powerful properties, peracetic acid 35% finds applications in many industries. Below are some of the most important areas where this disinfectant shines:

Food & Beverage Industry

Food safety is one of the top concerns in food production, and peracetic acid 35% is a key player in ensuring food is free of harmful pathogens. It’s commonly used to disinfect processing equipment, pipelines, storage tanks, and even fresh produce. By breaking down biofilms and eliminating bacterial contaminants, peracetic acid helps ensure the food reaching consumers is clean, safe, and pathogen-free.

Healthcare & Medical Settings

In healthcare, sanitation is non-negotiable. Peracetic acid 35% is often used for medical sterilization—especially in cases where instruments cannot be heat-sterilized. It’s ideal for delicate items like endoscopes and surgical instruments, ensuring that pathogens are eradicated without damaging sensitive tools. It’s also applied in surface cleaning within hospitals and clinics to keep spaces hygienic and safe.

Water Treatment

Water purification is another area where peracetic acid proves invaluable. It is used to disinfect both drinking water and wastewater. By breaking down organic contaminants and killing harmful microorganisms, peracetic acid helps maintain clean water for consumption and safe disposal in industrial and municipal settings.

Agriculture & Horticulture

Farmers and agricultural workers utilize peracetic acid 35% to disinfect equipment, greenhouses, and irrigation systems. It’s particularly effective in controlling fungi, molds, and other pathogens that could affect crops. By maintaining a clean environment, peracetic acid helps safeguard both crops and the workers handling them, promoting healthier yields.

Pharmaceutical Manufacturing

The pharmaceutical industry relies heavily on sanitized environments. Peracetic acid is essential in cleanroom environments, where contamination can have catastrophic effects on drug quality. It’s also used to clean the equipment and surfaces involved in the production of medications, ensuring that they remain free of bacteria, viruses, and other contaminants that could compromise the safety of the final product.

How Does Peracetic Acid 35% Stack Up Against Other Disinfectants?

It’s clear that peracetic acid has an edge over many conventional disinfectants in certain areas. Here’s why it’s preferred in so many high-stakes environments:

- Supercharged Oxidation: Peracetic acid is far more aggressive than chlorine bleach or even hydrogen peroxide, making it a more effective choice in environments where thorough sanitation is required.

- No Harmful Byproducts: Unlike chlorine-based solutions, peracetic acid breaks down without creating toxic or hazardous residues.

- Flexibility: Its ability to work at both high and low temperatures, along with its effectiveness in harsh conditions, means peracetic acid can tackle a broader range of applications.

- read more on that : https://www.researchgate.net/publication/14983219_Peracetic_Acid_and_Its_Application_to_Medical_Instrument_Sterilization

Safety Precautions When Using Peracetic Acid 35%

While peracetic acid is an amazing tool, safety should always be a top priority when handling such a powerful substance. Concentrated peracetic acid (35%) can be highly corrosive and should be approached with caution.

Here’s how to handle it safely:

- Protective Gear: Always wear gloves, goggles, and a face shield when working with peracetic acid to protect against splashes and fumes.

- Ventilation: Ensure that you’re working in a well-ventilated area to avoid inhaling vapors.

- Proper Storage: Store peracetic acid in a cool, dark place away from incompatible substances like strong bases, metal surfaces, or reducing agents.

- Dilution: Always follow proper dilution guidelines for your specific application to ensure you’re using the right concentration.

In case of a spill, quickly neutralize the substance with an appropriate neutralizing agent and dispose of it following local regulations.

The Future of Peracetic Acid 35%

As industries continue to push for safer, more sustainable practices, peracetic acid 35% is becoming a cornerstone of modern sanitation solutions. Its eco-friendly nature, combined with its ability to sanitize even in low temperatures, makes it ideal for today’s environmentally-conscious approach to disinfection. As more industries adopt it, we can expect to see even broader applications, from wastewater treatment to clean energy production.

In Conclusion: The Ultimate Sanitizer

Peracetic acid 35% is more than just a disinfectant; it’s an indispensable tool across several industries, helping to ensure that food, water, medical equipment, and other essential products are clean and safe. With its ability to kill a wide range of pathogens, break down into non-toxic byproducts, and perform in cold environments, peracetic acid proves time and time again to be an incredibly versatile and eco-friendly solution.

By understanding its properties, uses, and safety considerations, you can make the most of peracetic acid 35% and keep your environment cleaner, safer, and healthier. Whether you're looking to ensure food safety, improve water quality, or maintain hospital sterilization protocols, peracetic acid is the reliable disinfectant you can count on.

https://gentaur.com/products/peracetic-acid-35-id-286-p05020-01